Creating a Pipeline to a Growing Manufacturing Workforce

STEM has long been an area of opportunity and growth within the job market; however, employers still struggle to find candidates to fill the ever-changing and expanding skills gap. Community colleges are a ray of hope for both students and employers alike by offering realistic learning opportunities located within the communities students will serve. Daley College’s Manufacturing, Technology and Engineering Center (MTEC) is an example of a facility and curriculum that will help the City of Chicago prepare students for the more than 50,000 anticipated jobs coming to the region in the engineering and advanced manufacturing fields during the next decade.

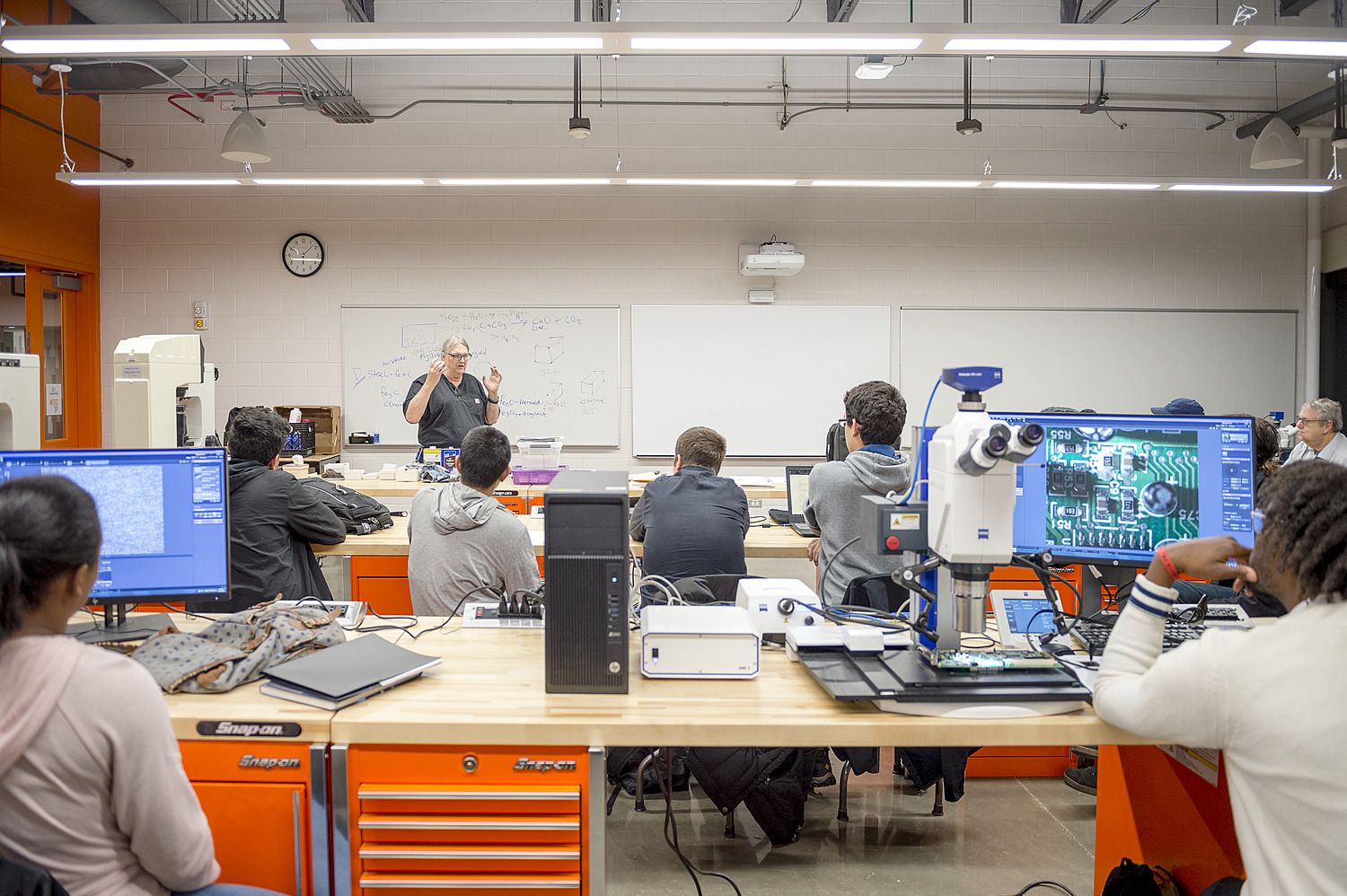

Spanning the main thoroughfare of 76th Street, the MTEC serves as a focal point and connector of the Richard J. Daley campus. The 63,200-square-foot building links the legacy college facility via a pedestrian bridge. Its interior includes an expansive high bay manufacturing space, six labs, four classrooms, administrative offices and communal areas for students that provide the skills and training needed for highly specialized, technology-oriented careers. Bright colors inside and out, along with seamless fluidity and transparency throughout the building, provide students, staff and the community a look into the future of manufacturing and STEM education.

“Industry partners are coming to our students before they graduate to hire them, not waiting for them to complete their programs.”

– Daley College President Janine Janosky

With planning origins that date back to 2013, this game-changing facility houses equipment that prepares highly skilled technicians in computer-integrated manufacturing, robotics, and factory automation for the regional economy. The advanced equipment – acquired through strategic industry partners such as American Gear Manufacturers Association – includes tabletop laser cutters, multi-axis CNC devices, additive manufacturing equipment, metrology instruments, CAD/CAM and other software, digital connectivity technologies and more.

While the building design is beautiful, it provides more for students and the surrounding community than just its physical presence. As the school itself serves a student population that is diverse in age, ethnicity and educational background, the building supports students on various education pathways to a career in advanced manufacturing: a 16-week basic certificate; an advanced certificate; an associate degree; and an educational path leading to a four-year college degree. This versatility is essential for local students to maximize utilization of the facility.

Academic programs housed at the MTEC include Communications Technology, Computer Numeric Control Machining, Electrical Construction Technology, Factory Automation, Quality Assurance, Welding, and more.

The MTEC celebrates manufacturing as a career requiring advanced skill and constant dedication. Its state-of-the-art technology offerings and spaces challenge students to work their hardest towards preparing for future job opportunities or transferring to four-year institutions.